Innovative Design

Compact Dimension

Variable filling Volume

User Friendly

Easy handling, intuitive operation

High Functionality

Insert bottom drawer

Mobile Liquid Addition System

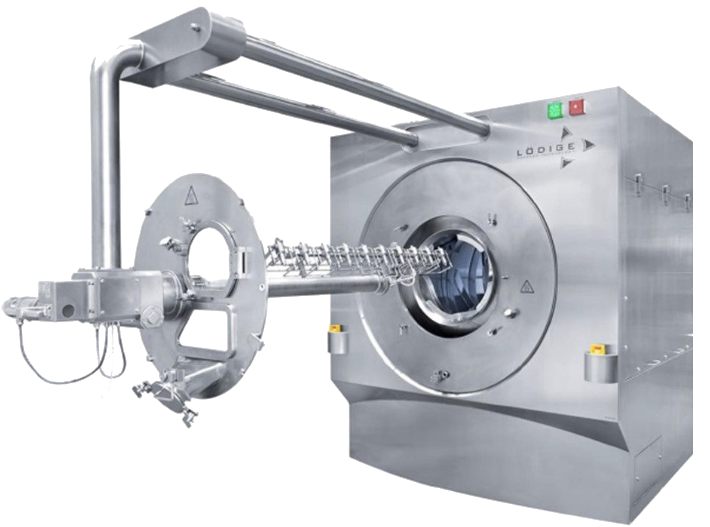

Coating of tablets is an amalgamation of spraying, mixing and drying process synchronized in appropriate settings to achieve supreme results. The Bectochem Loedige Coater are charismatic due to best in the industry mixing performance which results in a uniform application of coating.

The Bectochem Loedige lab scale system are used for research and development and process optimization.

The Modular Lab Coating System gives us a wider range of capacity i.e. min. of 0.6 kg to max. of 4.8 kg without an interchangeable pan design.

Being 100% scalable model, scalability studies have been well established too.

The design and features are similar to that of a production model in terms of

Drum Design

Baffle Design

Air Distribution

Spray Boom

The Bectochem Lödige Coater is designed for various Coating processes for a wide range of products such as tablets, mini tablets, pellets, caplets. Coating of pharmaceutical products in batch operation, thus providing an “all in one solution”. Bectochem Lödige supplies high-grade components, subsystems and systems for technical processing applications in a wide range of industries.

The Bectochem Lödige Coater operates on the principle of co-current under pressure process technology. Key advantages of the machines manufactured under the technology transfer are:

Highly Efficient and extremely fast coating process.

Very high Filling Variability.

Effective Mixing.

Best in class automation

Reduced batch time with Enhanced technology.

Operator Friendly system with ease of operation.

Reliable Scale Up Ensured.

Two additional nozzles for a maximised spray rate

Comfort Equipment: Control of air supply volume via FC, control of drum pressure via FC in the exhaust air

Mobile unit, contains: Magnetic agitator, mass flow sensor, hose pump, hose squeeze valve for circulation of the suspension

Machine line design for use of organic solvents (acetone, isopropanol, ethanol)

Portable panel with WinCC, FDA-CFR-21 part-11 conformity due to Siemens software “Log On”

Tablets of All Shapes

Mini Tablets

Sugar Coating tablets

Capsules

Pellets

Larger Granules

DIN EN ISO 9001

ASME-U_DESIGNATOR

CERTIFIED WELDING COMPANY

CHINESE MANUFACTURE LICENSE OF SPECIAL EQUIPMENT

KOREAN MANUFACTURE LICENSE OF SPECIAL EQUIPMENT

PRESSURE VESSELS

WE ARE THERE FOR YOU!!